The Basics of Structural Steel Fabrication – Why Structural Steel Is a good Choice

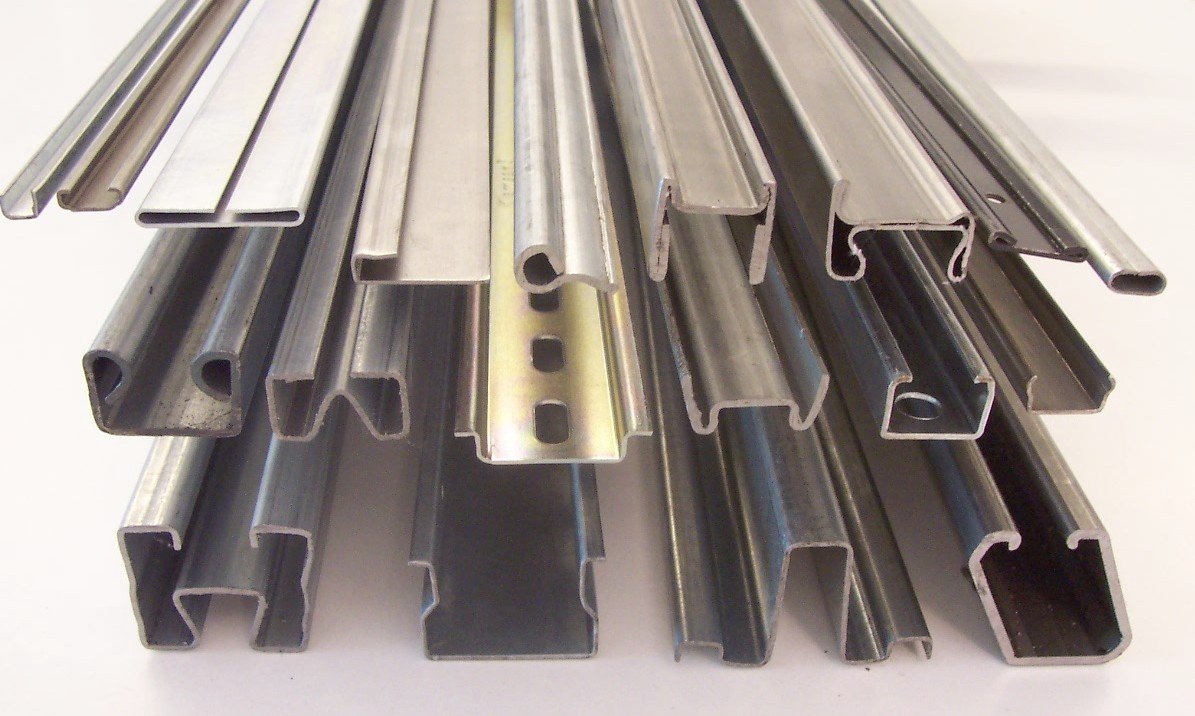

In most cases, structural steel may be the first and only option when building. There is a strong reason for that. Steel, and especially structural steel is really a long-lasting, durable and affordable material for any size project. For individuals who are unaware what all the fabrication process entails, it is a well-known process that is implemented to create steel parts which are joined and assembled to create a finished frame. These frames can and so are usually purchased by builders from structural steel fabricators, steel stockholders or steelmakers. They come in a huge selection of sizes and shapes but in case a builder finds that the particular shape they want isn't available; they can have it fabricated to their specifications. Using sections, structural steel fabricators can produce built-up girders which can be as strong as necessary by strengthening flanges and web, with regards to the load to be carried. In the steel factories of today, professionals use AutoCAD, a computer drafting program to build up structures and beams. This produces very accurate pieces that benefit both builders and the structural steel fabricators. Common Pieces and Parts There are several common pieces that structural steel fabricators use, they include plates and sections and of course bolts. The steel sections and plates are built to specification and may be for any size order normally, depending on the company chosen. Cutting, welding, drilling and Look at this website are the main process. Steel contractors typically get their plates and sections from the steel stockholder which are companies that ensure there's plenty of structural steel to meet the area's industry needs. They have a variety of parts including: � Plates � Light sections  � Flats � Angles � Cladding material � Structural sections � Bolts There are also what exactly are called “proprietary” products made from structural steel. These include fasteners, roofing systems, beams, purlins and much more outside of the more prevalent items built by structural steel fabricators. The Process There continue being many advances in productivity and quality so far as steel and its own construction worldwide. Developments in the specific machinery used will be the main contributors to the. Great site to heavy research being committed to this machinery, the industry is booming. 1. The plates and sections are sent to a steel stockyard. From there it will go to the fabrication lines for processing. steel fabrication is an extremely fast and streamlined process. 2. Shot blasting may be performed at this point, according to the structural steel fabricators choice. This prepares the surface for paint. 3. Pre-fabrication primers are applied (if desired). This helps maintain the pieces until a final paint coat is applied. 4. Sections are cut to length and plates are profiled to the chosen shape and size using automated machinery. Cutting is performed in many ways, including: � Circular saw � Gas � Flame � Plasma 5. Holes are drilled and punched 6. Bending is performed for curved structures; sections, plates and tubes could be bent. Welding One of the most important processes of steel fabricators is welding. It gets the joints ready to be connected on site also to be fastened to other fittings and fixtures. Various techniques are employed with heat to melt the joint set up, and a filler material is used for connecting and protect the joint fully and offer immense strength. Modern steel fabricators know that the procedure is complex and precise from the initial production of plates to transport and deliver everything must follow specific protocol in order to have a pristine finished product. They have an excellent management protocol set and procedure followed in order to meet industry requirements with ease. Knowing more about the process will certainly benefit any builder dealing with structural steel fabricators.

� Flats � Angles � Cladding material � Structural sections � Bolts There are also what exactly are called “proprietary” products made from structural steel. These include fasteners, roofing systems, beams, purlins and much more outside of the more prevalent items built by structural steel fabricators. The Process There continue being many advances in productivity and quality so far as steel and its own construction worldwide. Developments in the specific machinery used will be the main contributors to the. Great site to heavy research being committed to this machinery, the industry is booming. 1. The plates and sections are sent to a steel stockyard. From there it will go to the fabrication lines for processing. steel fabrication is an extremely fast and streamlined process. 2. Shot blasting may be performed at this point, according to the structural steel fabricators choice. This prepares the surface for paint. 3. Pre-fabrication primers are applied (if desired). This helps maintain the pieces until a final paint coat is applied. 4. Sections are cut to length and plates are profiled to the chosen shape and size using automated machinery. Cutting is performed in many ways, including: � Circular saw � Gas � Flame � Plasma 5. Holes are drilled and punched 6. Bending is performed for curved structures; sections, plates and tubes could be bent. Welding One of the most important processes of steel fabricators is welding. It gets the joints ready to be connected on site also to be fastened to other fittings and fixtures. Various techniques are employed with heat to melt the joint set up, and a filler material is used for connecting and protect the joint fully and offer immense strength. Modern steel fabricators know that the procedure is complex and precise from the initial production of plates to transport and deliver everything must follow specific protocol in order to have a pristine finished product. They have an excellent management protocol set and procedure followed in order to meet industry requirements with ease. Knowing more about the process will certainly benefit any builder dealing with structural steel fabricators.